BC Core Functions

Manufacturing

Manufacturing Module Overview

The Manufacturing module in Microsoft Dynamics 365 Business Central is a comprehensive solution designed to streamline production operations. Whether you operate in a make-to-order or make-to-stock environment, this module equips your team with the tools needed to plan, execute, and cost-manufacture processes with precision and flexibility.

Core Functions

-

Production Bill of Materials (BOMs): BOMs serve as the blueprint for your products, detailing every component required for assembly or production. Business Central allows you to define multiple BOM versions, supporting both simple and complex product structures.

-

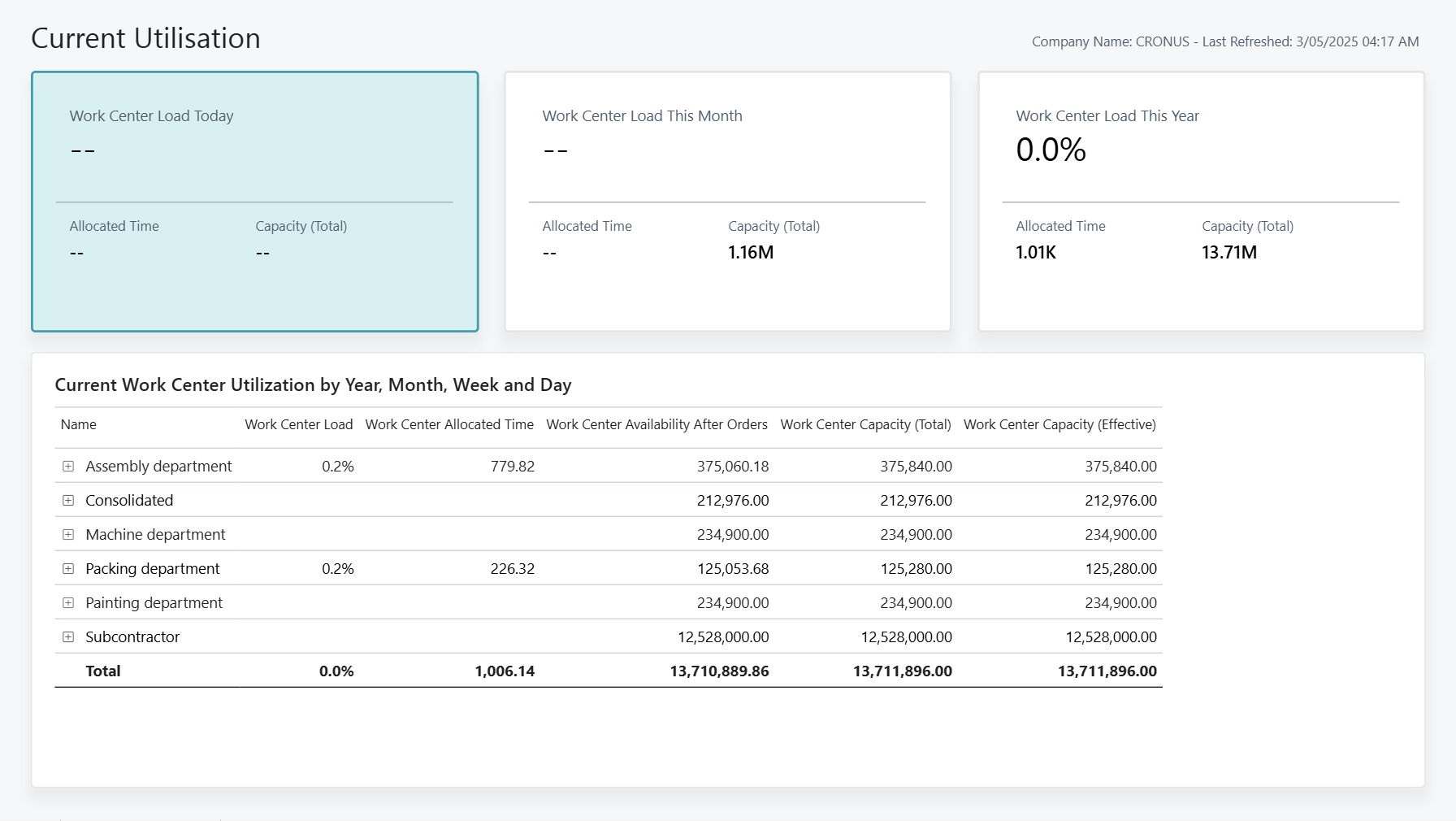

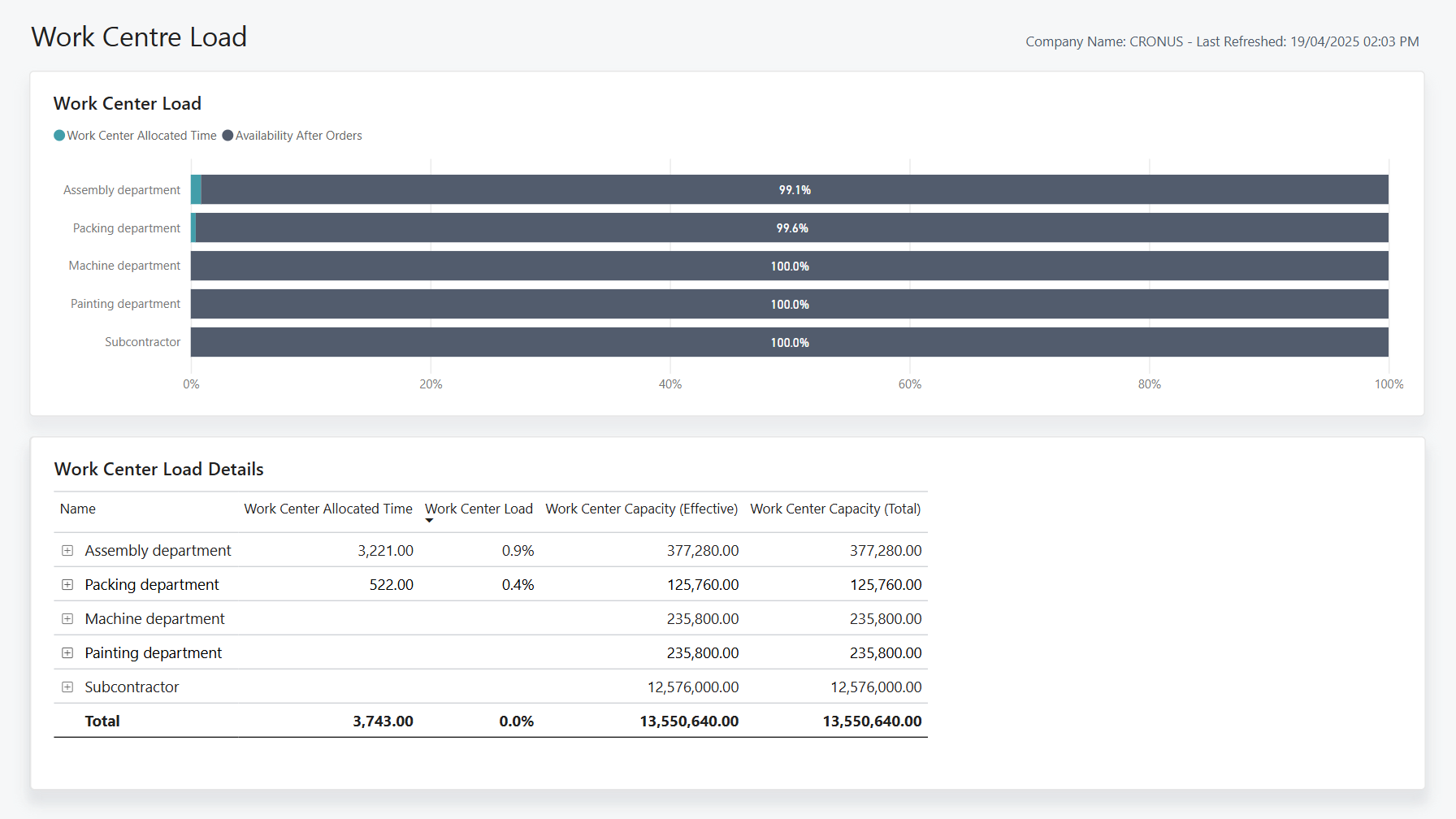

Routings and Work Centres: Routings define the step-by-step operations needed to manufacture a product, while Work Centres and Machine Centres represent the physical or logical resources used in production. These elements help optimise scheduling and resource allocation.

-

Production Orders: The system supports various production order statuses—Simulated, Planned, Firm Planned, and Released—allowing manufacturers to test, plan, and execute production workflows efficiently.

-

Master Production Scheduling (MPS) and Material Requirements Planning (MRP): MPS handles top-level demand planning based on forecasts and sales orders, while MRP calculates raw material and subassembly needs based on BOM structures. Together, they enable data-driven planning and inventory control.

-

Demand Forecasting and Capacity Planning: Business Central helps enable manufacturers to anticipate future demand and adjust production capacity accordingly. This includes setting up work centres to measure durations, loads, and throughput.

Costing Methodologies

Business Central supports full and flexible costing approaches, including:

- Standard Costing: Fixed cost per unit, ideal for predictable production environments.

- FIFO and Average Costing: Dynamic cost tracking based on inventory flow.

- Direct and Indirect Costs: Capture machine usage, labour, overheads, and consumables with granular control.

Cost roll-ups on item cards and real-time variance tracking ensure accurate financial insights across the production lifecycle.

Advantages for Customers

- Unified Operations: Integrates planning, production, and accounting into a single platform.

- Scalability: Supports growth with flexible configurations for multiple sites, product lines, and production types.

- Efficiency Gains: Automates scheduling, order creation, and costing—reducing manual effort and improving delivery accuracy.

- Visibility and Control: Real-time dashboards and Power BI integration offer actionable insights into production performance and cost drivers.